Samsung recently announced a massive recall involving 180,196 vehicles from Ford, Audi and Stellantis.

The National Highway Traffic Safety Administration (NHTSA) pointed out that the diaphragms of the battery cells of these

vehicles are damaged, which may cause fires during long-term charging and discharging.

This recall has once again made the issue of battery safety the focus of the industry. As one of the key components of lithium

batteries, the quality of the separator is directly related to battery life and safety.

The influence of membrane surface wettability on battery performance

The membrane is located between the positive and negative electrodes, and has the function of preventing battery short

circuit and transmitting ions. It needs to have high porosity and the ability to evenly infiltrate the electrolyte.

Insufficient membrane wettability will result in the electrolyte being unable to fully infiltrate the membrane pores, affecting

ion transmission, resulting in increased internal resistance, increased interface impedance, and even thermal runaway, seriously

affecting battery safety.

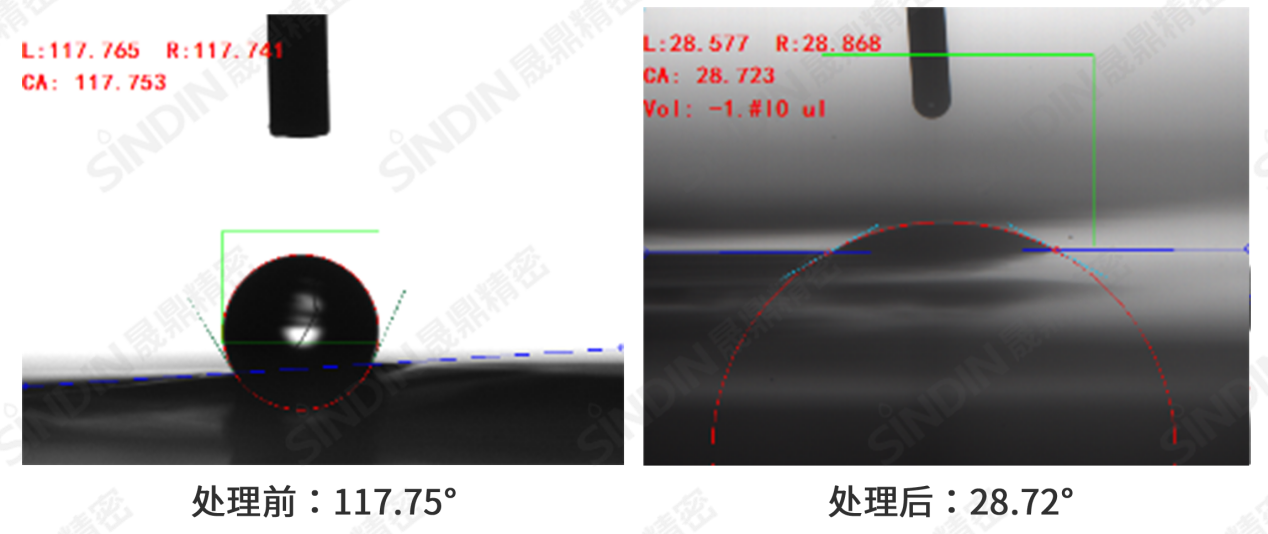

Plasma treatment improves the surface wettability of lithium battery separators

Plasma surface treatment technology uses high-energy particles to bombard the material surface, changing the surface chemical and physical properties, thereby improving wettability.

*DBD plasma cleaner

Equipment advantages

① Wide processing area: large-area processing can be achieved (sindin can achieve 800mm width processing),

which helps to improve production efficiency;

② Uniform processing effect: the processing effect is more uniform and stable, which can meet the processing requirements

of lithium battery separators;

③ Low processing temperature: the processing temperature is lower to avoid thermal damage to the separator.

Plasma treatment of lithium battery separators

Plasma surface treatment can introduce polar groups on the separator surface to increase surface energy, enhance the

wettability of the separator and electrolyte, and reduce safety issues during battery charging and discharging.

*Lithium battery separator, source: Internet, please delete if infringed

It can be seen from the above figure: after plasma treatment, the water drop angle of the diaphragm is reduced to 28.72°, and its surface hydrophilicity is improved, which effectively improves the compatibility between the diaphragm and the electrolyte, thereby improving the conductivity and charge and discharge performance of the battery.